We currently offer a wide selection of brands (over 100 different labels among the most prestigious in the eyewear industry) as well as a very large choice of frames (over 10,000 references listed on our site). We've also chosen to offer you Mymonture frames, which we sell at a price we think is fair. Today, we take a closer look at the eyewear we're all so proud of.

100% handmade frames

Mymonture frames are first and foremost quality eyewear, handcrafted in cellulose acetate by professionals, enabling us to offer you a unique product of the highest quality. Round, square or Wayfarer-style, there's something for everyone in our Mymonture selection. You can also take a look at our article, which frame to choose according to my face shape if you're still unsure.

But what exactly is acetate?

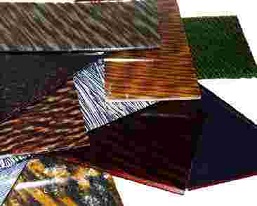

Cellulose acetate plates

Acetate is a plastic material commonly used in the eyewear industry to manufacture frames, and synonymous with quality. Also known as cellulose acetate, it is obtained from cotton, which classifies it as a "natural polymer" material.

Acetate is therefore a hypoallergenic material, which is a real plus and makes it suitable for anyone, even people with fragile skin. What's more, because it's derived from cotton, it has the particularity of being flexible without deforming.

Used as an eyewear material, acetate is made up of sheets glued together, but it is also possible to use other components in the manufacture of eyewear, such as fabric, which is sometimes used by major eyewear brands during the manufacturing process.

The acetate eyewear manufacturing process

The question that springs to mind is: how do you make glasses from an agglomerate of plates glued together? Let's take a brief look at the various steps involved.

First of all, for the face of the frame, starting from the acetate plate, holes are made corresponding to the future location of the lenses, which corresponds to the inner contouring.

Next comes the outer contouring, removing material to reveal a sketch of the future frame.

The frame is then slightly arched and polished, depending on the desired look.

Next comes the production of the temples, starting from the same base as the frame face, namely an acetate plate. A metal frame is inserted into the temple to ensure rigidity. As with the frame face, the temples are polished and curved to match the shape of the frame.

The face of the frame and the temples are then assembled using various metal parts known as "hinges", which may or may not be spring-loaded.

Our Mymonture collection

Mymonture model CONNOR

Mymonture DONATO model

Mymonture model MILES

Our Mymonture collection includes many handcrafted acetate frames, as explained above, but also metal frames conceived and designed with the same care as acetate frames.

And, of course, to guarantee your complete satisfaction, all Mymonture frames come with a two-year warranty.

First and foremost, Mymonture is our promise to provide you with brand-neutral, high-quality frames that have been inspected by us, at a very affordable price.

Loading...

Loading...